Production Ramp up of Audio Products

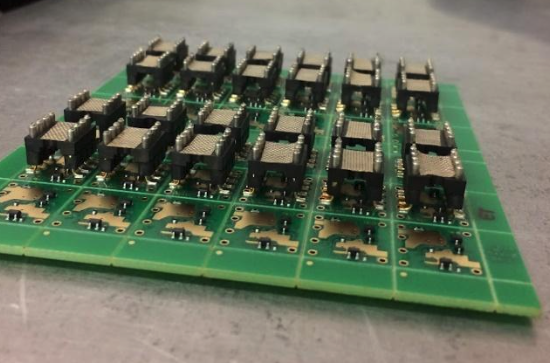

From 10 units to 10s of Thousands of units, Sparkos Labs has enjoyed rapid growth thanks to Tracer’s focus on Design for Manufacturability and Engineering feedback.

Company Overview

Sparkos Labs, Inc. operates out of Westminster Colorado and specializes in high end audio components, design, and gear. The company’s competitive advantage resides in its ability to produce a superior (sounding) audio product, both from an engineering and manufacturing standpoint.

Problem

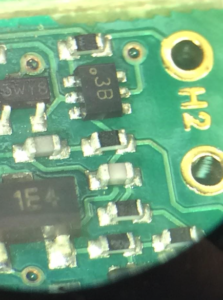

After only a year from its inception, Sparkos Labs was gaining notoriety in the online audio community. Enthusiasts and audiophiles all around the globe were reviewing Sparkos Labs products (namely a Discrete Op Amp product), making review videos and writing blogs, and as a result the orders started to pile up. At the time, Sparkos Labs was performing all SMT assembly in house- the products were essentially hand crafted, one unit at a time. The strategy here was to 1) minimize costs and 2) maintain a high level of control over the quality of the products. Just one shoddy solder joint on their sensitive audio products could have a measurable impact on audio quality and as a result tarnish the company’s high end reputation. As larger audio distributors started to take notice, Sparkos Labs faced what many would call a good problem: How to scale production in a way that was cost effective in order to meet their growing demand, but yet maintain their in-house laboratory level quality in order to preserve the Sparkos Labs brand.

Action

Right off the bat, it was very important to the customer that all parts were consigned. This allowed for enhanced supply chain control by Sparkos Labs and kept costs low since it avoided a mark-up on parts by Tracer.

Another important requirement set forth by Sparkos Labs was the ability to perform a First Article test, meaning calibrate and verify functionality of the first unit coming off the production line before all subsequent units are produced. This was critical for Sparkos Labs because many of their products needed to be calibrated and trimmed (resistor values changed based on a variety of material and design tolerances) and to replace thousands of resistors manually would be a big waste of time. The first article test also included rigorous inspection of tiny solder joints under high magnification, in order to detect previously known issues that Sparkos Labs had learned about during their assembly experience.

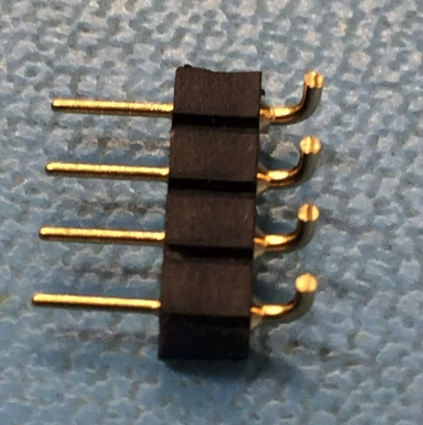

After multiple meetings and a few low volume assembly runs, it was clear that Tracer needed to increase build efficiency in order to meet Sparko’s cost requirements. After performing labor analysis, it became clear that the soldering of a custom audio connector was a significant labor and cost driver.

The connector, in its delivered state, was not able to be connected/soldered via automated SMT processing, and therefore was installed manually after SMT.

Solution

Unlike other contract manufacturers who have more rigid procurement strategies, Tracer accepts both consigned parts kits or can buy parts in a turnkey arrangement, so there was no problem meeting Sparkos Labs initial consigned part requirement.

With regards to the first article test, on every build-Tracer was able to provide a test bench and microscope for a Sparkos Labs technician to perform first article calibration, verification, and feedback to the Tracer production team. Not only did this on site first article process help Tracer to perfect reflow profiles and other parameters to the customer’s liking- but it also educated Sparkos Labs personnel on the challenges around their designs and exactly where improvements could be made.

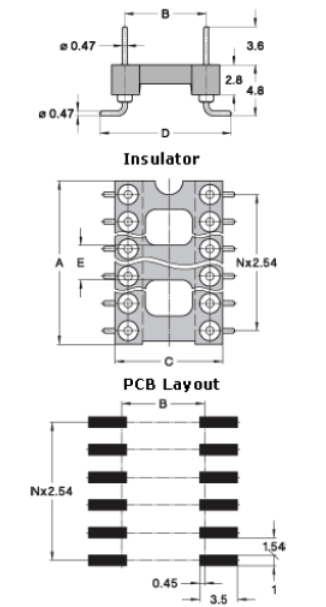

Finally, to solve the labor issue on the part pictured above, Tracer Engineers developed both short term and long term plans. In the short term, a socket for the connectors would be ordered, and modified at Tracer so that it could be loaded onto a JEDEC Matrix tray and then utilized by the pick & place machine, just like any other SMT component.

To solve the problem permanently, Tracer Engineers spec’d out a completely new, off the shelf component that would replace Sparkos initial audio connector, and which would be compatible with an automated soldering process. Tracer also outlined the necessary changes to the product design for consideration by Sparkos Labs. This suggestion was immediately adopted by Sparkos Labs and saved the company money both on components since the connectors were no longer custom parts, and also on Tracer’s assembly costs since it enabled a more efficient assembly method.

Results

As Sparkos Labs moved more and more of its in house PCB Assembly activities to Tracer, the company was able to dedicate more resources to what it did best- designing new audio products! With Tracer’s help, Sparkos Labs easily met the rising production demands of its customers and continues to develop and produce world-class Hi-Fi Audio products.

“Tracer graciously allowed me to be heavily involved in the production ramp up of my product. I’ve learned so much about the process-it’s made me a better engineer.”

-Andrew Sparks, Sparko’s Labs, Inc.

Conclusion

Certain products simply require a high level of collaboration between designer and supplier in order to successfully get to market. Tracer’s flexible and dynamic services provide its customers with unmatched opportunity for process involvement and control, while is focus on Engineering and problem solving fosters an innovative environment.