History

The story of Tracer Inc. can truly be traced back to Hungary a half dozen years after the end of World War II. There, in Budapest, a young married couple, Gabor and Margit Toth were starting their family and career in a country recently devastated by war and in the grip of a totalitarian communist regime.

In this bleak setting, Gabor had, in 1955, graduated with a degree in Electrical Engineering from The Budapest University of Mechanical and Electrical Engineering. He continued rising in the ranks of the nationalized Railroad Company, and was responsible for critical communication electrical switchgear in Budapest. The outlook for the Hungarians was miserable in these days, and led to the heroic but short lived Hungarian Revolution in late 1956.

Gabor played out his role as a true patriot, assisting in relaying Russian troop movement information to the Hungarian freedom fighters and to remnants of the patriotic Hungarian Army.

The revolution was brutally suppressed by the Russian army, and retributions began. Knowing his life was at risk, Gabor and his family, including Margit, and children Ildiko, Andy, and Martha, left Hungary, escaping across the border, opting for a better life elsewhere. After stays in Austria and Switzerland, Gabor and his family emigrated to the United States, and settled in Southern California.

In the United States, Gabor enjoyed a long and satisfying career as an Electrical Engineer. It is amazing to contemplate that leaving one of the world’s worst places in 1956, he was able to guide his family to one of the best places, Southern California, by 1959. He worked for companies including Northrop, Bendix, Burgmaster Tools, and SMT Dynamics. He capped his career at SMT Dynamics, where he worked and contributed for close to 20 years.

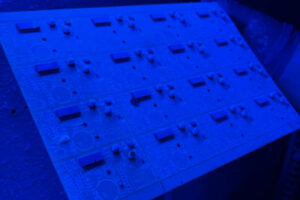

The decade of the 80’s saw a real change in electronics packaging. The advent of the printed circuit board became widely accepted in the 1960’s, and printed circuit boards became the building blocks for electronic packaging. By the 1980’s, packaging evolution led to the introduction of surface mount technology.

Andy Toth, Gabor’s son, saw the opportunity to explore an emerging new technology in electronics, namely SMT. Andy at the time was a principal in a consulting company focusing on defense, high tech, and related industries. In 1986, he formed and capitalized SMT Dynamics, an early SMT based company. SMT Dynamics enjoyed growth and expansion, and it was in this environment that Andy started bringing his young son Tyler to work with him on the occasional Saturday.

SMT Dynamics was successfully sold to a Colorado based company in 1994, and Andy and his family, including Tyler relocated to Evergreen, CO.

In 1996, Andy formed The Wytan Corporation, in Golden, CO, and again, self-capitalized, starting the growth process. In addition to SMT, Wytan also offered advanced packaging solutions, including chip on board, direct die attach, flip chip, and other related services.

The company grew, and had its share of success, including patents co-developed with Displaytech and Hana Technology. Customers of note included Motorola, Medtech div. of Johnson and Johnson, Cooper Tire and Rubber, Goodyear, Sea Ray div. of Brunswick Boat Group, and others.

Tyler had been involved with Wytan over the years. Starting with summer jobs as a solder and test tech, and eventually an SMT Pick & Place machine operator. He had gained an intimate understanding of the process, equipment, and the technology that just cannot be learned in a classroom. After his graduation from the University of Denver with an MBA in 2013, Tyler worked full time as Wytan’s Sales Manager.

By 2014, Tyler had worked his way up to President of Wytan. Realizing the need for major strategic business improvement, including equipment upgrades, specialized assembly lines, and a change in ownership of the company, Tyler proposed a plan to dissolve the corporation. The proposal was accepted by all stakeholders involved and permitted Tyler to establish a new and improved operation.

In early 2016, Tyler incorporated Tracer Inc., and continues today as the 3rd generation of the Toth family in electronics. Since 2016, Tracer has seen year over year growth. This growth has been both market driven, as regional Colorado tech industries have grown substantially in the past 6 years, but also has been facilitated by Tyler’s ability to organize the right people, processes, equipment, and business strategy in a way that compliments those growing industries.